ENERGY SAVINGS THROUGH HEAT RECOVERY

ENERGY SAVINGS THROUGH HEAT RECOVERY

INTRODUCTION

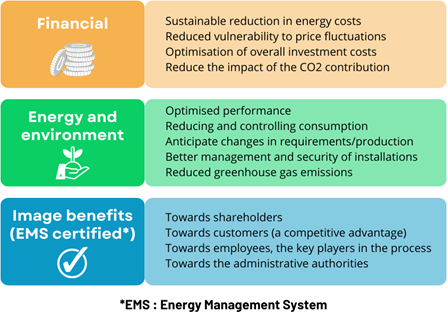

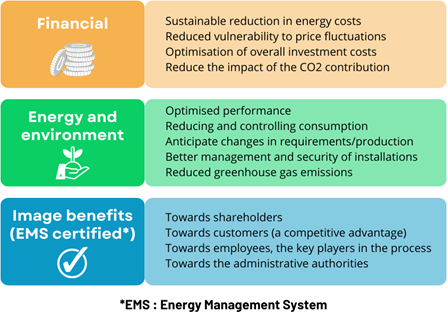

Are you looking to make energy savings by using heat recovery systems on refrigeration installations? Food industry processes require refrigeration, but also essential heating and hot water for washing, processing, defrosting and everyday use. Environmental and legislative issues are driving the need to increase the efficiency of systems by :

Environmental and legislative issues are driving the need to increase the efficiency of systems by :

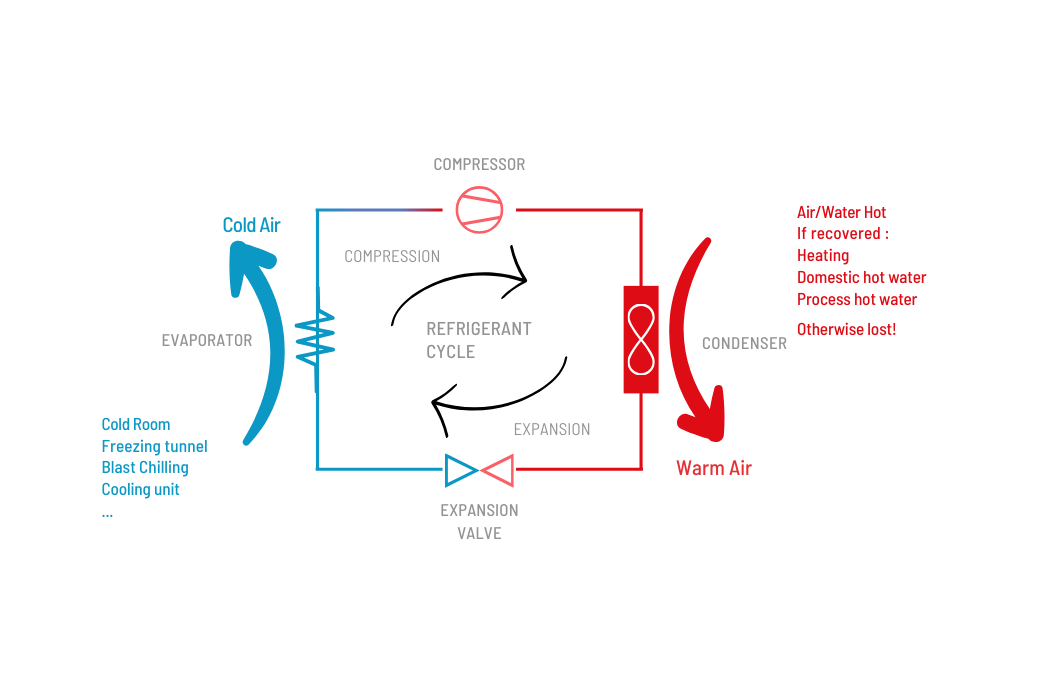

HEAT RECOVERY

HEAT RECOVERY

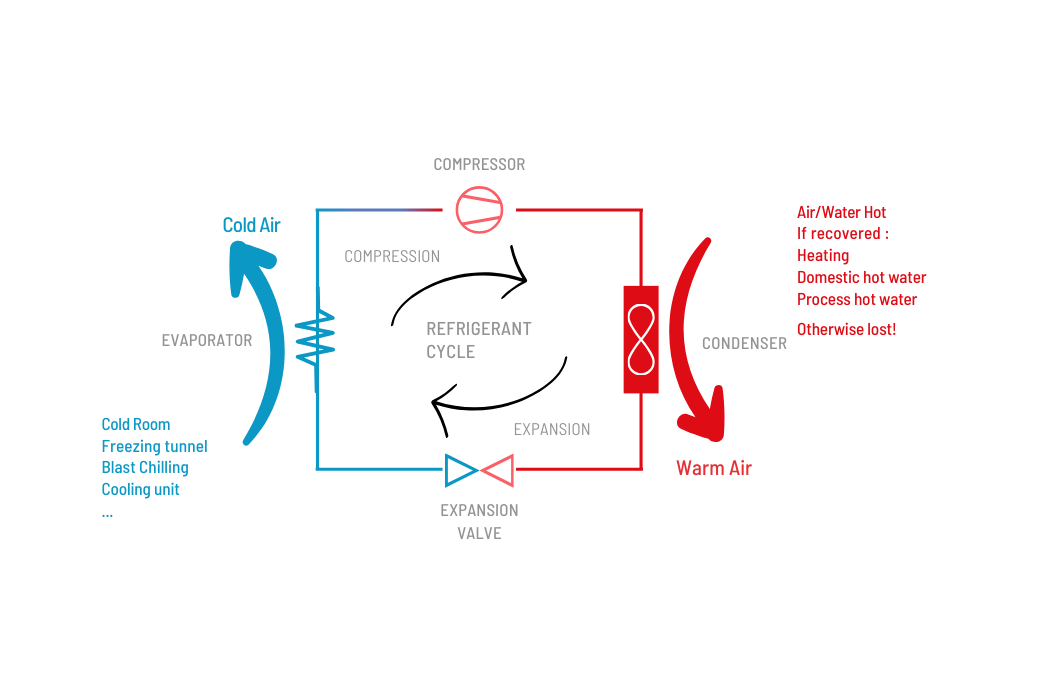

For a refrigeration plant, cooling is nothing other than extracting a quantity of heat from a system or product and transferring it to its external environment, which is air and water. The quantity of heat that can be recovered from a specific installation is the result of the refrigeration output added to the electrical power consumed by the compressors to produce this refrigeration. The heat recovered can reach the condensing capacity. CONCLUSION

CONCLUSION

There are other ways of recovering heat from a refrigeration plant:

Are you looking to make energy savings by using heat recovery systems on refrigeration installations? Food industry processes require refrigeration, but also essential heating and hot water for washing, processing, defrosting and everyday use.

- Saving energy

- Reducing CO2 emissions

- Compliance with current directives

- Lower production costs

- Research into financial savings

- Reducing consumption

For a refrigeration plant, cooling is nothing other than extracting a quantity of heat from a system or product and transferring it to its external environment, which is air and water. The quantity of heat that can be recovered from a specific installation is the result of the refrigeration output added to the electrical power consumed by the compressors to produce this refrigeration. The heat recovered can reach the condensing capacity.

There are other ways of recovering heat from a refrigeration plant:

- Subcooling

- Desuperheating

- Recovery from oil coolers

- Electricity consumption

- Gas consumption

- Water consumption

- Wastewater treatment

- Maintenance